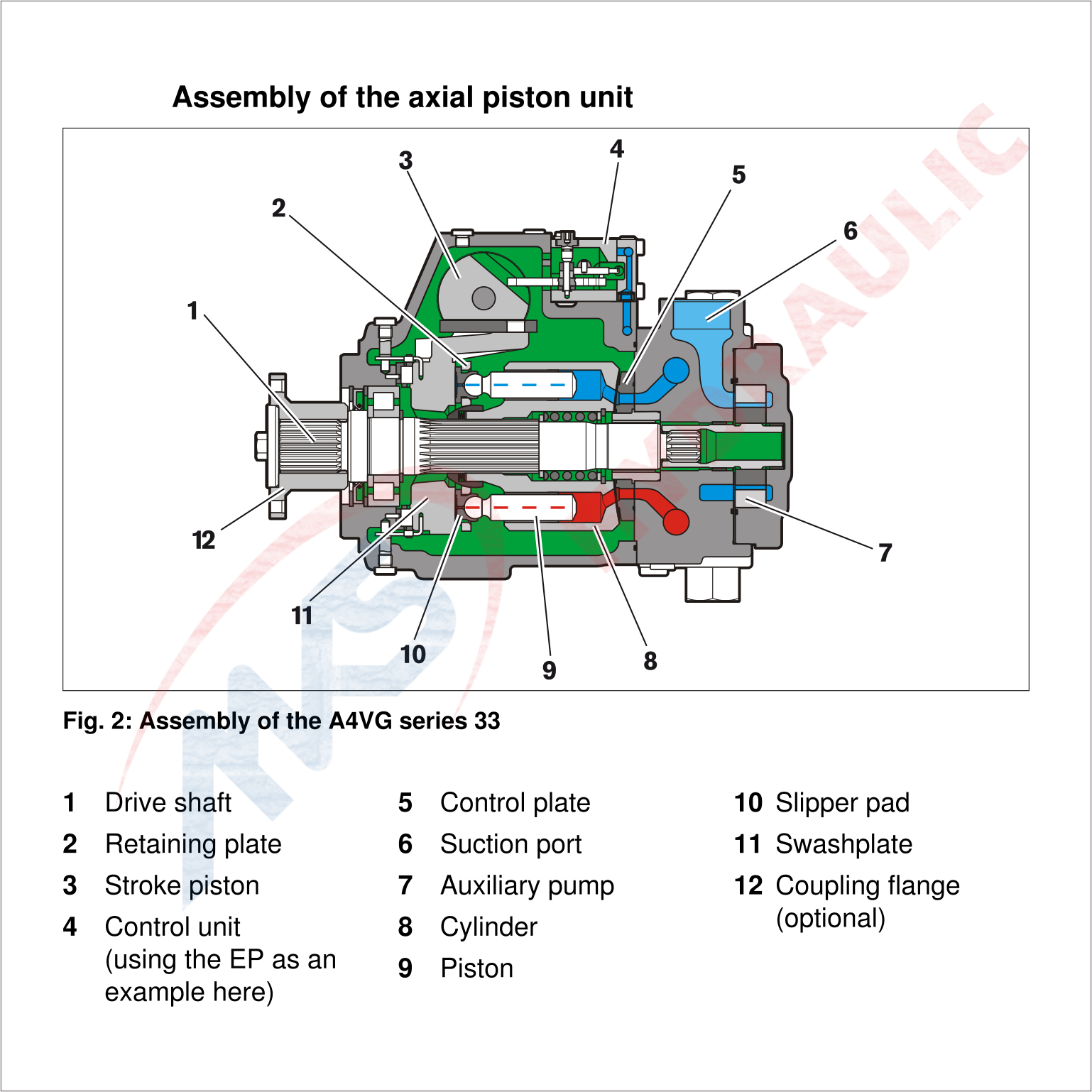

A4VTG Variable Closed circuit pumps , High pressure Axial piston variable pump

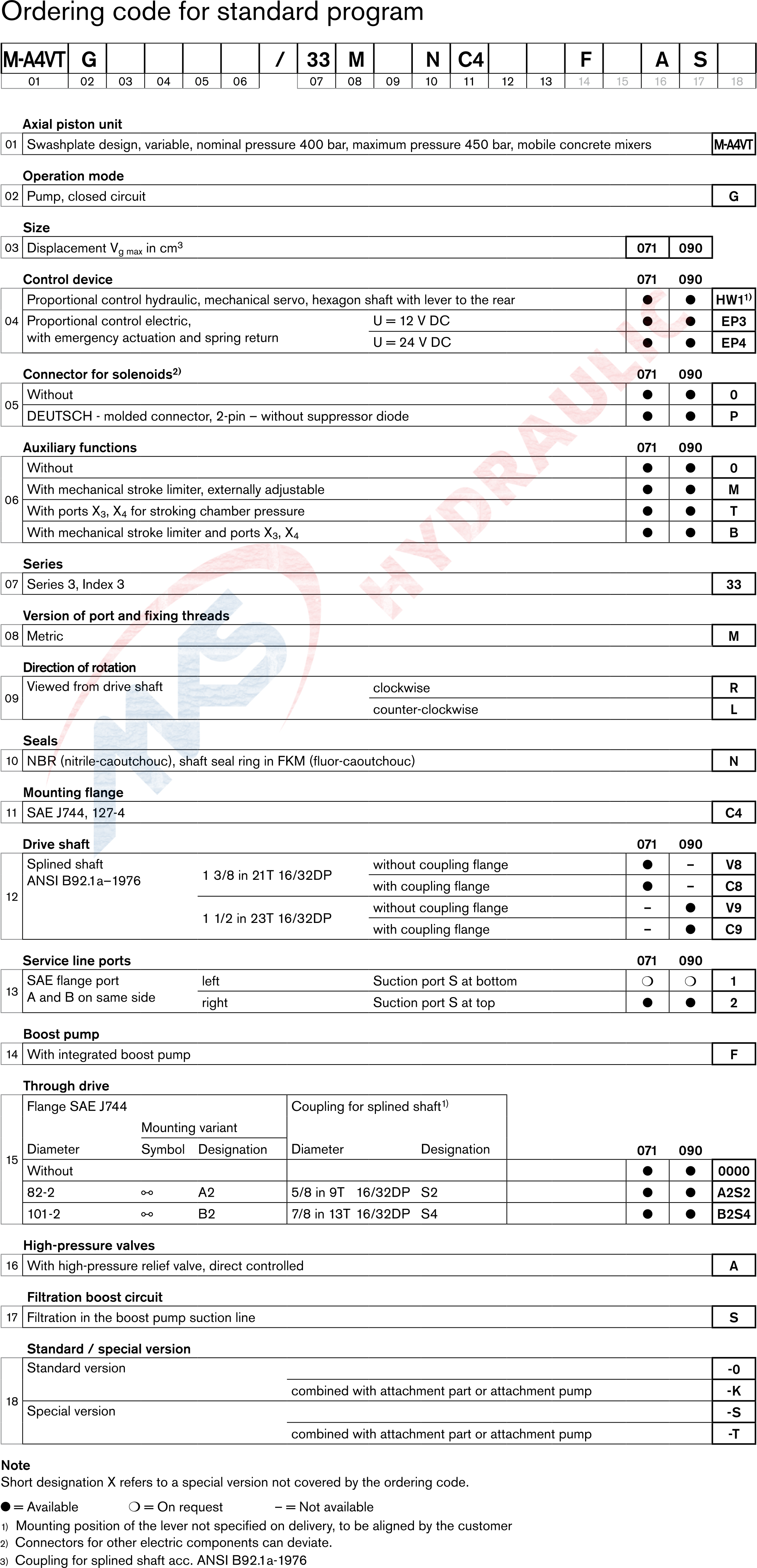

Control device

HW – Proportional control hydraulic, mechanical servo

The output flow of the pump can be steplessly varied in the range between 0 to 100 %, proportional to the rotation of the control lever between 0° and ±29°.

A feedback lever connected to the stroke piston maintains the pump flow for any given position of the control lever between 0° and 29°..

EP – Proportional control electric

The output flow of the pump can be steplessly varied in the range between 0 to 100 %, proportional to the electrical current supplied to solenoid a or b.

The electrical energy is converted into a force acting on the control piston. This control piston then directs control hydraulic fluid into and out of the stroke cylinder to adjust pump displacement as required.

A feedback lever connected to the stroke piston maintains the pump flow for any given current within the control range.

Technical data

Series 33.

Sizes NG71, 90.

Nominal pressure 400 bar.

Maximum pressure 450 bar.

Closed circuit.

For the drum drive in mobile concrete mixers.

Features

––Variable axial piston pump of swashplate design for hydrostatic drives in closed circuit

––The flow is proportional to the drive speed and displacement.

––The flow increases as the angle of the swashplate is adjusted from zero to its maximum value.

––Flow direction changes smoothly when the swashplate is moved through the neutral position.

––Two pressure-relief valves are provided on the high pressure ports to protect the hydrostatic transmission (pump and motor) from overload.

––The high-pressure relief valves also function as boost valves.

––The integrated boost pump acts as a feed pump and control pressure supply.

––The maximum boost pressure is limited by a built-in boost pressure-relief valve.